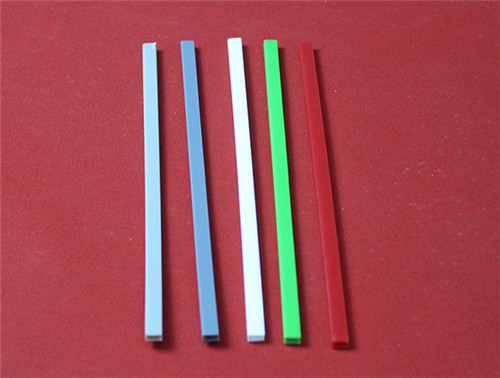

Custom plastic extrusion is a manufacturing process used to create long, continuous plastic products with a specific cross-sectional profile. This method is highly versatile and allows for the production of complex shapes and designs tailored to the unique needs of various industries. Custom plastic extrusion is widely used in sectors such as construction, automotive, consumer goods, and electronics due to its efficiency, cost-effectiveness, and ability to produce high-quality, durable products.Actually, it’s not just this reason, PVC sealing strip Its own advantages are also obvious, and it is normal for the market to perform well. https://www.jiepeng-plastic.com/

The Process of Custom Plastic Extrusion

The custom plastic extrusion process involves several key steps:

1.Material Selection:

The first step in custom plastic extrusion is selecting the appropriate plastic material. Common materials include PVC, polyethylene, polypropylene, ABS, acrylic, and polycarbonate. The choice of material depends on the specific requirements of the final product, such as flexibility, strength, temperature resistance, and chemical resistance.

2.Melting:

The selected plastic material is fed into an extruder, a machine consisting of a hopper, a heated barrel, and a screw. The plastic is heated and melted as it moves through the barrel.

3.Extrusion:

The molten plastic is then forced through a custom-designed die that shapes the plastic into the desired cross-sectional profile. The die can be created to produce a wide range of shapes, including tubes, channels, angles, and more complex geometric designs.

4.Cooling:

After exiting the die, the extruded plastic is cooled to solidify its shape. This cooling process can involve air cooling, water baths, or cooling rolls, depending on the type of plastic and the specific application.

5.Cutting and Finishing:

Once the plastic has cooled and solidified, it is cut into the required lengths. Additional finishing processes, such as trimming, drilling, or coating, may be applied to achieve the desired final product.

Applications of Custom Plastic Extrusion

Custom plastic extrusion is used in a variety of applications across different industries:

1.Construction:

In the construction industry, custom extruded plastic profiles are used for window and door frames, weatherstripping, siding, and decorative trim. These profiles provide durability, weather resistance, and low maintenance.

2.Automotive:

The automotive industry uses custom plastic extrusion for components such as trim, seals, gaskets, and protective guards. These parts are essential for vehicle assembly, providing both functional and aesthetic benefits.

3.Consumer Goods:

Custom extruded plastic profiles are found in numerous consumer goods, including furniture edging, toys, packaging materials, and home appliances. These products benefit from the versatility and cost-effectiveness of plastic extrusion.

4.Electronics:

In the electronics industry, custom plastic extrusion is used to create housings, enclosures, cable management systems, and insulating components. These profiles offer electrical insulation, protection, and organization for electronic devices and systems.

Benefits of Custom Plastic Extrusion

Custom plastic extrusion offers several advantages:

1.Versatility:

Custom plastic extrusion allows for the creation of a wide range of shapes and sizes, making it suitable for diverse applications.

2.Cost-Effectiveness:

The extrusion process is efficient and produces minimal waste, leading to lower production costs compared to other manufacturing methods.

3.Durability:

Extruded plastic profiles are durable, resistant to weathering, chemicals, and UV radiation, ensuring long-lasting performance.

4.Customization:

The ability to design and produce custom dies means that products can be tailored to meet specific requirements and standards, providing bespoke solutions for different industries.

Conclusion

Custom plastic extrusion is a highly adaptable and efficient manufacturing process that plays a critical role in various industries. By allowing for the production of customized, high-quality plastic profiles, it meets the specific needs of construction, automotive, consumer goods, and electronics sectors. The versatility, cost-effectiveness, and durability of custom extruded plastic profiles make them an invaluable component in modern manufacturing.