Automobile circuit board, that is, printed circuit board for automobile. As the carrier of on-board electronic equipment, it plays a vital role in the operation of the car. However, what’s so special about it that it stands out from ordinary circuit boards? This article will take you to know more about this different car circuit board, and let’s take a look at it below.Therefore, we should understand pcb assembly manufacturer Many benefits, absorb and summarize, and use them. https://intechcircuit.com/

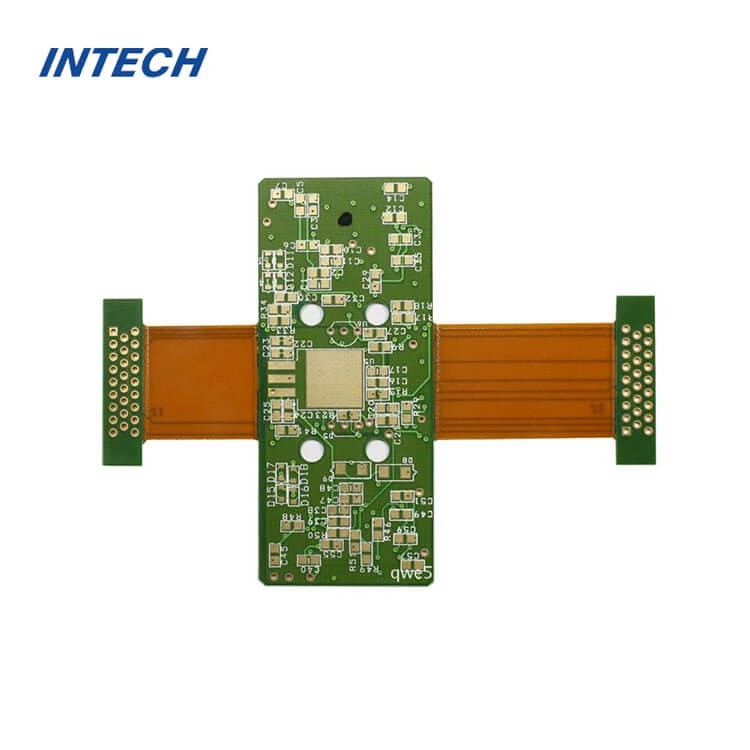

First, the concept and composition of automobile pcb board is an important component used to install electronic components and provide connection paths in various electronic equipment and systems of vehicles. It usually consists of a substrate, conductive paths, circuit components, etc.

The substrate material of automobile pcb board is mainly made of materials with high temperature, heat resistance, moisture resistance and corrosion resistance to meet various challenges of automobile environment. Conductive paths are usually printed on the substrate. These copper conductive paths are called printed circuits, which connect circuit components and form current paths. Circuit components, such as resistors, capacitors, inductors, diodes, transistors, etc., are the key components of automobile circuit boards, which are indispensable for controlling automobile power system, environmental awareness, navigation and other functions.

Second, the application field of automobile circuit board The complexity of modern automobile far exceeds the mechanical equipment that was visible to the naked eye of the driver. The automobile pcb board has been applied in many fields. For example, the power control system is used to control the whole power system of the automobile, including engine, transmission, brake, etc. Vehicle information system, used to realize navigation, communication, entertainment and other functions; Safety control system, including body stability system, airbag control, etc.; Environmental awareness systems, such as reversing radar, raindrop detection and so on. Each function needs to design and manufacture automobile pcb, which has strict requirements on the performance of automobile pcb.

Third, the function and characteristics of the automobile pcb board, the biggest function of the automobile pcb board is undoubtedly to provide a path for connecting electronic components and forming current for various electronic equipment and systems of the automobile. Its performance parameters mainly include high temperature resistance, vibration resistance, humidity resistance and corrosion resistance. Because of the complexity of automobile working environment, automobile pcb board needs to deal with many harsh environments such as high temperature, humidity, vibration and impact, so it has high requirements on weather resistance and strength in material selection and design, and is more powerful than ordinary circuit boards.

Fourth, the difference between automobile pcb board and ordinary circuit board Compared with ordinary circuit board, automobile pcb board has significant differences in many performances. The main difference is higher weather resistance and strength. There are higher requirements for the design and manufacture of automobile pcb boards, which need to meet the harsh working environment of automobiles and their complex and changeable functional requirements. Automobile pcb board also has higher vibration resistance and waterproof performance, and pays more attention to environmental protection, because for outdoor equipment like automobiles, vibration resistance, waterproof and environmental protection are particularly important. The automobile pcb board may be more complex and refined than the ordinary circuit board, because all kinds of precise control and adjustment functions in the automobile system need to be realized by electronic circuits, and this requires a more refined and complex circuit.

High temperature resistance, vibration resistance, humidity resistance, corrosion resistance and other properties make the automobile pcb board work stably in the complex and harsh automobile environment. Compared with ordinary circuit boards, automotive pcb boards are more elaborate and complex, and meet various functional requirements at the same time, showing its superiority and complexity. Understanding these is of great significance for us to better understand the automobile pcb board and its important role in the automobile electronic system.

There are many different classifications of circuit boards, and in order to be effectively applied in different fields, it has also put forward different high requirements. In the actual automobile manufacturing, it needs to achieve higher performance in order to be better used.