In the realm of printed circuit boards (PCBs), the rigid 6-layer FR4 circuit board stands out for its versatility and reliability. These boards are widely used in various applications, from consumer electronics to industrial machinery, owing to their excellent electrical performance and mechanical stability. In this blog post, we’ll delve into the specifics of rigid 6-layer FR4 circuit boards, their benefits, applications, and why they are a preferred choice for many engineers and manufacturers.It is strictly required by such a standard, customized oem pcb Only with today’s development scale, can we have the proud momentum to crush our competitors. https://www.hongmycircuits.com/

What is a Rigid 6-Layer FR4 Circuit Board?

A rigid 6-layer FR4 circuit board is a type of multilayer PCB constructed with six layers of conductive material (usually copper) separated by layers of insulating material, most commonly FR4 (Flame Retardant 4). The “rigid” designation indicates that the board is not flexible and maintains its shape under mechanical stress.

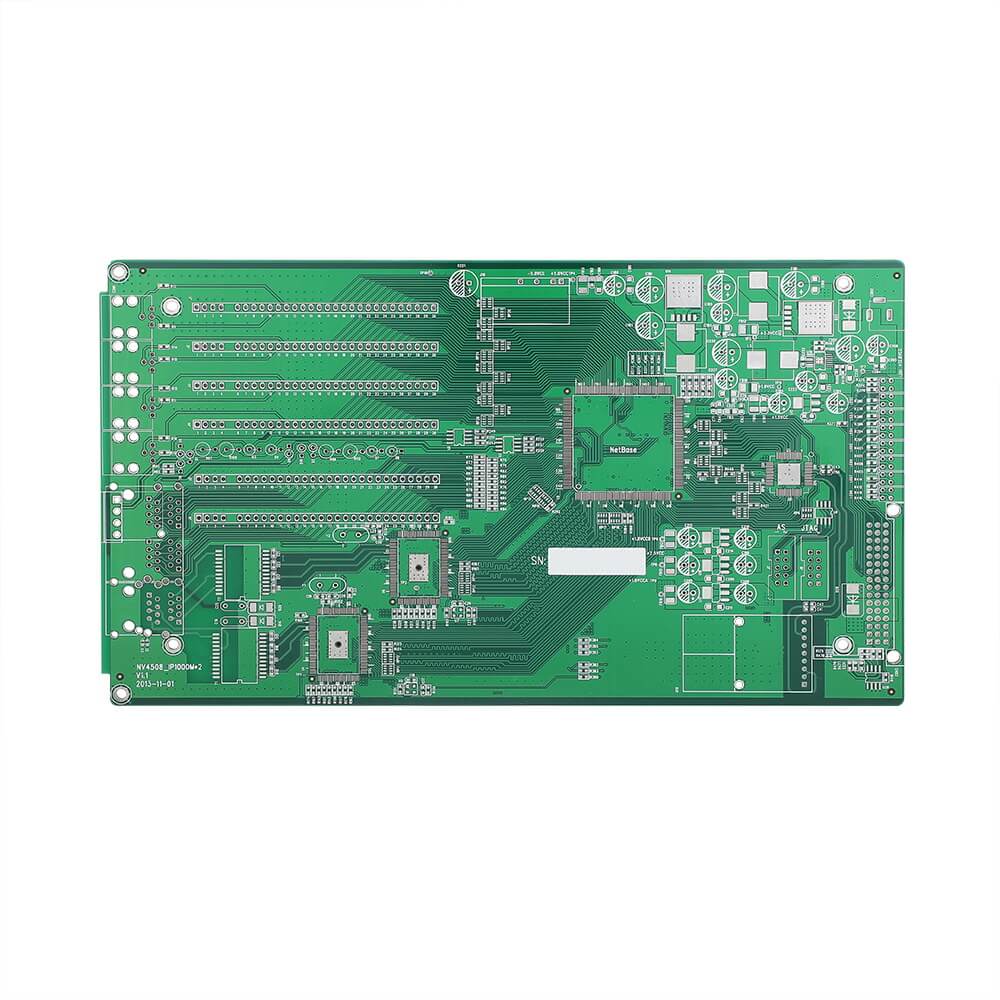

Rigid 6 Layers Fr4 Circuit Board Green Solder Mask PCB

Key Features of Rigid 6-Layer FR4 Circuit Boards

1. Multilayer Construction

The 6-layer design provides ample routing space for complex circuits. This allows for greater component density and more intricate circuit designs compared to single or double-layer boards.

2. FR4 Material

FR4 is a widely used PCB substrate material known for its excellent thermal, electrical, and mechanical properties. It provides strong insulation between layers, ensuring signal integrity and stability.

3. High Reliability

Rigid 6-layer FR4 boards are known for their durability and reliability. The rigid structure provides mechanical support, reducing the risk of damage due to flexing or bending.

4. Enhanced Performance

With multiple layers, these boards can handle higher power loads and support more complex circuits. This makes them ideal for high-performance applications where reliability and precision are crucial.